The Seychelles is an archipelago of 115 islands located in the Indian Ocean, off East Africa. Its dependence on imports, its sea-locked territory in nature, and home to just under 100,000 residents, represents a unique challenge to those in charge of the country’s vital infrastructure.

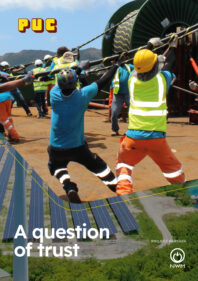

Noemie Chetty is the Director of Procurement of the Seychelles’ Public Utilities Corporation (PUC) and it’s her job to ensure that equipment and materials required to provide the islands with electricity, water, and sewage treatment, services are readily available. In fact, PUC is the only source of provision of electricity on the main islands of the Seychelles and so not only is this a challenging role in any given circumstance, but it’s an especially demanding set against a post-pandemic, geo-politically uncertain landscape.

“Always expect the unexpected,” says Chetty as we join her from her Seychelles base. “It’s our role to make sure that our services are not getting impacted,” she adds. “Our supply chain nowadays is so, so volatile with all of these disruptions.”

PUC is currently unable to practice lean procurement due to the need for buffer stock as they simply don’t know what might happen along the supply chain. “The war, natural disasters, global warming, all of this is having an impact on our operations,” Chetty explains.

As Seychelles is a sea-locked country, any adverse effect in the global market or a natural disaster can severely affect the shipment and the equipment needed for energy production such as generator spares parts and other equipment PUC needs. “We have altogether thirty (33) generator sets (18 on Mahé, 13 on Praslin and 2 on La Digue) and they cost us a lot of money to maintain and operate,” she says. “I cannot put an exact figure on it per year, because it will depend on the number of purchases in lieu of planned maintenance work but as an example, a single unit of turbocharger costs hundreds of thousands of Euros, so you can imagine the scale for all the required spares. And so, any delay from the supply chain side, be it at the manufacturing level or logistics level, can have an impact on our operations.”

One recent goods shortages causing Chetty and her team issues involves calcium hypochlorite, which is used to treat water. “There have been recent explosions at ports where calcium hypochlorite is shipped,” she explains. “It’s being banned in some ports and shipping lines are very, very cautious on accepting this kind of cargo, because it’s becoming a major safety concern.” As a counter measure, the Corporation is gearing up its adoption of electrolysis technology by installing new units at its main water treatment plants which will produce the chemicals needed to treat water, on-site. “These are all aspects of supply chain management where we need to find new solutions to our problems,” she reveals…